Product: Disposable sterile syringe push rods (Common materials: medical - grade PP, PE)

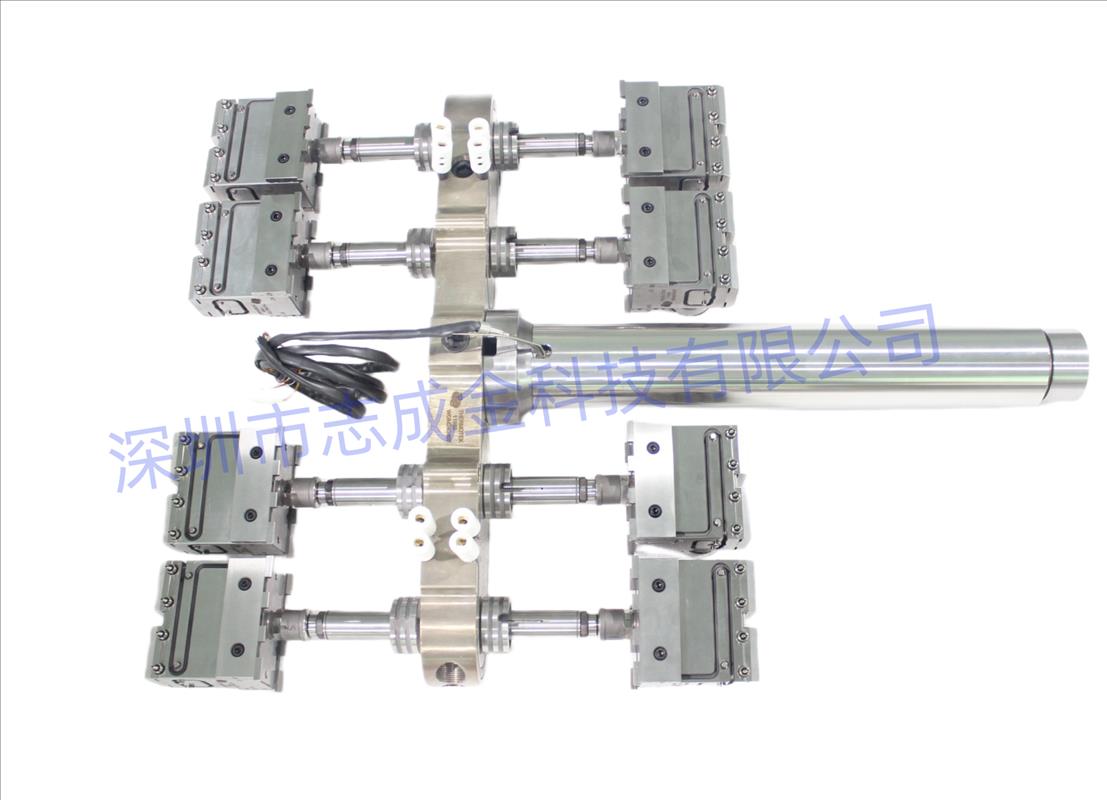

Mold Configuration: 32 + 32 - cavity stack injection mold + multi - point side - gate hot runner system

Core Challenges:

-

The gate must not affect the sealing performance of the top of the push rod and the thrust surface at the end.

-

The dimensional and weight deviations of the 64 - cavity products

need to be strictly controlled within a very small range (±0.03mm).

-

Meet the strict requirements of the medical industry for high - capacity production, low cost, and zero defects.

32 + 32 Side - Feeding Stack Mold Hot Runner Solution:

-

Side - gate Design: The gate is precisely positioned in the middle

of the side wall of the push rod, perfectly avoiding the functional

areas. No secondary processing is required after ejection.

-

Hot Runner Balancing System: Adopt multi - stage manifold plates and

needle - valve hot nozzles (optional), combined with precise

temperature control to ensure extremely uniform filling of the 64

cavities.

-

High - Rigidity Stack Mold Structure: Special guiding and clamping

designs ensure accurate alignment of the upper and lower molds during

long - term operation and stable production.

Achievements:

-

Soaring Production Capacity: The output per single machine has increased by over 100%, significantly reducing the unit cost.

-

Worry - free Quality: The CPK of key product dimensions is ≥1.67.

The gate position is perfect, and both the appearance and functions meet

the standards 100%. The customer complaint rate is close to zero.

-

High - Efficiency Automation: Seamlessly integrated into the

automated production unit, reducing manual labor and improving overall

efficiency and cleanliness.

-

Drastic Reduction of Waste: No cold - runner waste, with a significant increase in material utilization rate.

_副本_副本.jpg) 【 Patent Product 】 1-out 96 side glue hot runner system

【 Patent Product 】 1-out 96 side glue hot runner system

![[Patented product] 48-Cavity Two-Gate Hot Runner System](/cut_285_238/Data/szzcj/upload/image/20221018/80_副本.jpg) [Patented product] 48-Cavity Two-Gate Hot Runner System

[Patented product] 48-Cavity Two-Gate Hot Runner System

16-chamber hot runner system for double-side glue feeding

16-chamber hot runner system for double-side glue feeding

![[Patented product] 1 out 64 side glue feeding system](/cut_285_238/Data/szzcj/upload/image/20220924/_MG_0408_副本.jpg) [Patented product] 1 out 64 side glue feeding system

[Patented product] 1 out 64 side glue feeding system

![1. 64-side glue feeding system [extended version]](/cut_285_238/Data/szzcj/upload/image/20221227/IMG_0967_副本1.png) 1. 64-side glue feeding system [extended version]

1. 64-side glue feeding system [extended version]

【 Patent Product 】 1. 48 side glue inlet system

【 Patent Product 】 1. 48 side glue inlet system